Cabinet making is a specialised woodworking trade that involves the design, construction, and installation of cabinets, furniture, and other storage units. Cabinet makers use a variety of tools and techniques to create cabinets that are both functional and aesthetically pleasing.

The main focus of cabinet making is to create cabinets and storage units that are durable, functional, and tailored to the specific needs of the customer. Cabinet makers may work with a variety of materials, such as wood, plywood, or composite materials, and use a range of woodworking techniques, such as joinery, carving, and veneering.

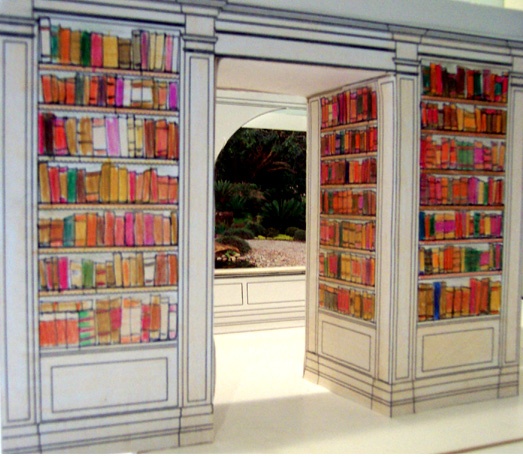

Cabinets can be designed for many different purposes, such as kitchen cabinets, bathroom vanities, bookcases, wardrobes, and entertainment centre’s. Cabinet makers often work closely with architects, interior designers, and homeowners to ensure that their cabinets are not only functional, but also match the overall design aesthetic of the space.

Groth and Sons have decades of hands-on experience in interior architecture, construction and design. We’re a family of cabinet makers with an unparalleled reputation in Sydney for producing exceptional quality bespoke cabinetry and interior architecture. Best cabinet makers Sydney Eastern Suburbs.

Early history of cabinet making

Cabinet making has a rich and extensive history, dating back to ancient times. The earliest cabinets were used to store valuables and were often made of wood or other natural materials.

The ancient Egyptians, Greeks, and Romans all used cabinets for storage and display. These early cabinets were often decorated with intricate carvings and ornamentation and were made of wood, metal, or other natural materials. The cabinets were often designed to hold valuables such as jewellery, artefacts, or scrolls.

During the Middle Ages, cabinets became more widespread and were used to store a variety of items. They were often large and ornate, with intricate carvings and inlays. The most skilled cabinet makers during this time were often associated with guilds, which regulated the quality of their work.

Cabinet making flourished though the Renaissance, particularly in Italy and France. Cabinets became more sophisticated and were designed to serve a variety of functions, including storage, display, and writing. The cabinets were often made of expensive materials such as ebony, ivory, or mother-of-pearl and were decorated with elaborate carvings and inlays.

During the 18th and 19th centuries, cabinet making continued to evolve, with a focus on functionality and practicality. Cabinets were designed to be more portable, with smaller, lighter designs that could be easily moved. The use of veneers and other techniques allowed for more intricate designs and patterns. The Industrial Revolution had a significant impact on the cabinetry industry, transforming the way that cabinets were designed, produced, and distributed. The Industrial Revolution brought about the development of new manufacturing techniques, such as assembly-line production and machine-made parts. This allowed for the mass production of cabinets, making them more affordable and accessible to a wider range of people. The use of new materials such as cast iron, steel, and plastic, allowed for the development of new cabinet designs and production methods. The development of new transportation methods, such as railroads and steamships, cabinets to meant works could be transported more quickly and efficiently, expanding the market for cabinetry. The Industrial Revolution also brought about a move towards standardization, with the development of standard sizes and designs for cabinets. This allowed for greater efficiency in production and reduced costs. It also brought about a spirit of innovation and experimentation, leading to the development of new and creative designs for cabinets. This led to new styles and forms of cabinetry that were not possible before.

In the 20th century, cabinet making became more streamlined and focused on modern, minimalist designs. The use of new materials such as plastic, steel, and glass allowed for more creative designs and streamlined production. Today, cabinet making continues to evolve, with a focus on sustainability, innovative design, and new technology.

There have been many influential people throughout history who have made significant contributions to the craft, design, and technique development of cabinet making and have helped shape the craft and continue to inspire and influence modern cabinet makers today. Here are a few notable figures:

Thomas Chippendale: Chippendale was an 18th-century British cabinet maker and furniture designer who is known for his ornate, Rococo-style furniture designs. His book, “The Gentleman and Cabinet-Maker’s Director,” is considered a seminal work in the history of furniture design and cabinet making.

Gustav Stickley: Stickley was an American furniture maker and designer who is known for his Arts and Crafts style furniture. He believed in simple, functional design and his furniture pieces were characterized by clean lines, sturdy construction, and natural materials.

George Hepplewhite: Hepplewhite was an English furniture designer and cabinet maker who was active in the late 18th century. He is known for his elegant, neoclassical-style furniture designs, which featured delicate proportions and decorative details such as inlaid wood.

James Krenov: Krenov was a Swedish-American woodworker and author who is known for his influential book “The Fine Art of Cabinet Making.” Krenov emphasised the importance of craftsmanship and creativity in cabinet making and his approach to furniture design continues to be influential today.

Sam Maloof: Maloof was an American woodworker and furniture designer who is known for his unique, sculptural furniture designs. He was known for his attention to detail and his use of traditional woodworking techniques.

Digital design has influenced cabinet making

Digital design software has revolutionised the cabinet making industry, allowing designers and manufacturers to create highly detailed and precise designs with unprecedented speed and accuracy. Digital design software has greatly improved the efficiency of the design process, allowing designers to create complex and highly detailed designs with greater speed and accuracy than traditional methods. Designers can now create highly realistic 3D visualisations of their designs, helping clients to better understand how the final product will look and function in their space. It also allows designers, manufacturers, and clients to collaborate on cabinet projects, as designs can be easily shared and modified in real time.

Digital design software makes it easier create customised cabinets, as designers can easily modify designs to meet the specific needs and preferences of their clients and allows for highly precise measurements and cuts, resulting in cabinets that fit together perfectly and function seamlessly. This also helps to reduce costs by minimising material waste, optimising manufacturing processes, and improving overall efficiency.

Basic principles of cabinetry design

Cabinetry design is an important aspect of creating functional and aesthetically pleasing furniture pieces. The basic principles of cabinetry design include the following:

Functionality: The primary purpose of cabinetry is to provide storage space and functionality. Designers should consider the specific needs of the user when creating cabinets, including the type and amount of items to be stored, accessibility, and ease of use. The design should also consider the space available and the overall layout of the room.

Proportion and Scale: The size and proportions of cabinets should be appropriate for the space in which they will be used. Cabinets that are too small or too large for the room can disrupt the visual balance of the space. Cabinets should also be scaled appropriately to the other elements in the room, such as doors, windows, and furniture.

Balance and Symmetry: Cabinets should be balanced visually, both within themselves and in relation to the other elements in the room. Symmetry is often used in cabinetry design to create a sense of order and balance. However, asymmetrical designs can also be used effectively to create interest and visual appeal.

Material and Finish: The material and finish of the cabinets should complement the overall style of the room. Wood is a common material used in cabinetry, but other materials such as metal or glass can also be used to create unique and interesting designs. The finish of the cabinets should also be considered, as it can affect the overall look and feel of the room.

Details and Accessories: The details and accessories of the cabinets can add interest and functionality to the design. This can include elements such as decorative mouldings, hardware, and lighting. These details should be carefully chosen to complement the overall design and add to the functionality of the cabinets.

By considering these principles, designers can create cabinets that are not only functional but also visually appealing and complementary to the overall design of the space.

The cabinet making process

The cabinet making process involves several stages, including planning, design, material selection, fabrication, assembly, and installation.

Planning: The planning stage involves determining the purpose of the cabinet, the location where it will be installed, and the desired style and design. The cabinet maker will also take measurements of the space where the cabinet will be installed to ensure a perfect fit.

Design: Once the purpose and design of the cabinet are established, the cabinet maker will create a detailed design plan that includes the dimensions, materials, hardware, and any special features.

Material Selection: Based on the design plan, the cabinet maker will select the appropriate materials for the cabinet, including wood, plywood, MDF, or other composite materials. They will also choose the hardware, such as hinges, drawer slides, and knobs.

Fabrication: The fabrication stage involves cutting the materials to the appropriate size and shape, using various tools such as saws, routers, and sanders. The cabinet maker will also drill holes for hardware, make grooves for joinery, and create any necessary decorative elements.

Assembly: The assembly stage involves joining the various parts of the cabinet together using woodworking joinery techniques such as dovetails, dowels, or mortise and tenon. The cabinet maker will also install the hardware and any other components such as shelves or drawers.

Finishing: The finishing stage involves sanding the cabinet to create a smooth surface, and then applying a finish such as paint, stain, or varnish. This stage helps to protect the cabinet from moisture and other environmental factors.

Installation: Once the cabinet is complete, it is installed in the desired location. The cabinet maker may need to make minor adjustments to ensure a perfect fit.

Each of these stages requires specific tools, skills, and techniques to ensure a high-quality, functional, and beautiful result.

Essential tools used in cabinet making

Cabinet making is a specialised craft that requires the use of a variety of tools to create high-quality and functional cabinetry. The essential tools used in cabinet making include hand saws, chisels, hand planes, handheld drills, clamps, table saws, miter saws, routers, jigsaws, and drill presses. These tools help cabinet makers achieve precision, accuracy, and efficiency in their work, resulting in beautiful and functional cabinetry.

The tools used in cabinet making can be broadly divided into two categories: hand tools and power tools.

Hand Tools

Hand saws: Hand saws are used for cutting wood. They come in different shapes and sizes, such as rip saws, crosscut saws, and panel saws. A rip saw is used to cut wood along the grain, while a crosscut saw is used to cut across the grain.

Chisels: Chisels are used for carving and shaping wood. They come in different sizes and shapes, such as gouges, skew chisels, and straight chisels.

Hand planes: Hand planes are used for smoothing and shaping wood surfaces. They come in different sizes, such as block planes, jack planes, and smoothing planes.

Handheld drills: Handheld drills are used for drilling holes in wood. They come in different sizes and shapes, such as cordless drills and impact drivers.

Clamps: Clamps are used to hold wood pieces together while glue is drying. They come in different sizes and shapes, such as bar clamps, pipe clamps, and hand screw clamps.

Power Tools

Table saws: Table saws are used for cutting large sheets of wood into smaller pieces. They come in different sizes and shapes, such as bench-top saws, contractor saws, and cabinet saws.

Miter saws: Miter saws are used for making precise angled cuts in wood. They come in different sizes, such as compound miter saws and sliding compound miter saws.

Router: Routers are used for cutting decorative shapes in wood. They come in different sizes and shapes, such as plunge routers and fixed-base routers.

Jigsaw: Jigsaws are used for making curved cuts in wood. They come in different sizes and shapes, such as cordless jigsaws and barrel grip jigsaws.

Drill press: Drill presses are used for drilling precise holes in wood. They come in different sizes, such as bench-top drill presses and floor drill presses.

Hand tools and power tools are both essential in cabinet making, but there are situations where one tool is more appropriate than the other. Hand tools provide greater precision and control than power tools, particularly when working with intricate designs and delicate materials. For example, hand saws and chisels allow for greater precision when cutting curves, intricate shapes, or mortises and tenons. In contrast, power tools may be better suited for larger or more repetitive cuts, such as crosscuts, rip cuts, or dados.

Power tools are generally faster than hand tools, particularly when working with large pieces of wood or thick materials. For example, table saws and miter saws can quickly and accurately cut large pieces of wood to size, whereas hand saws may be more time-consuming for this type of task. Power tools can also be more efficient for repetitive cuts, such as cutting multiple boards to the same length or angle. Power tools generate more noise and dust than hand tools. When working with power tools, it is important to wear appropriate personal protective equipment, such as earplugs, goggles, and respirators, to protect against dust and noise pollution. In contrast, hand tools generate little to no dust or noise, making them a good choice for small or indoor spaces.

Hand tools require more skill and practice to use effectively than power tools, particularly when it comes to hand saws and chisels. For example, using a hand saw to make a precise cut requires a steady hand and a lot of practice. In contrast, power tools such as miter saws and routers can be easier to use and require less skill to achieve good results. When deciding which type of tool to use, consider the specific task at hand, your skill level, and the environment in which you are working.

Evolution of cabinet makers tools and project planning

The history of cabinet making tool development dates back to ancient times when people used simple tools made of stone, bone, and wood. Over time, with the development of metalworking, more advanced tools were invented, such as saws, planes, and chisels.

In the 19th century, the Industrial Revolution led to a major shift in cabinet making tool development. Machines such as lathes, planers, and shapers were invented, which greatly increased the efficiency and productivity of cabinet makers. With these machines, they could produce large quantities of furniture more quickly and at a lower cost.

In the 20th century, the invention of power tools revolutionised cabinet making once again. Power tools such as table saws, routers, and drills made it easier and faster to create intricate designs and precise cuts, allowing cabinet makers to push the boundaries of design and produce complex and innovative pieces.

With the advent of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies in the latter half of the 20th century, the process of cabinet making has become even more streamlined and precise. These technologies allow cabinet makers to create highly detailed and accurate designs, which can be translated into machine-readable code for automated manufacturing.

As a result of these technological advancements, the field of cabinet making has become more accessible to a wider range of people, including hobbyists and DIY enthusiasts. With the availability of affordable power tools and CAD software, more people can take on cabinet making projects and experiment with their own designs.

The evolution of cabinet making tool development has had a profound impact on project planning and design. With the availability of more advanced tools, cabinet makers can create more complex and intricate designs, as well as produce furniture more efficiently and cost-effectively. Furthermore, with the use of CAD software, they can visualise and test their designs before beginning the production process, allowing for greater precision and accuracy. Overall, the development of cabinet making tools has allowed for greater creativity, efficiency, and precision in the craft, and has made it more accessible to a wider range of people.

Common materials used in cabinetry

Cabinetry is an essential part of home design and can greatly affect the overall look and feel of a space. One of the most important considerations when it comes to cabinet design is the choice of materials. There are many different materials that can be used in cabinetry, each with its own unique properties and advantages.

Solid wood is a traditional and popular choice for cabinetry. It is a durable and long-lasting material that can be stained or painted to match any design style. Oak, maple, and cherry are among the most popular types of wood used in cabinetry. Solid wood is also relatively easy to work with, making it a popular choice for DIY cabinet makers. Plywood is a composite material made up of thin layers of wood veneer that are glued together. It is a strong and stable material that resists warping and shrinking. Plywood is also a cost-effective alternative to solid wood and can be used for both the cabinet boxes and doors. Medium Density Fibreboard (MDF) is a composite material made from wood fibres and resin. It is an affordable and versatile material that is often used for cabinet doors and panels. MDF can be painted or covered with a veneer to create a variety of finishes. Particleboard is a composite material made from wood particles and resin. It is a cost-effective alternative to solid wood and can be used for the cabinet boxes and shelves. However, it is not as strong as plywood or MDF and can be prone to warping and moisture damage.

Laminate is a synthetic material made from layers of paper or fabric that are infused with resin. It is a durable and low-maintenance material that is often used for cabinet doors and countertops. Laminate is available in a wide range of colours and patterns, making it a versatile choice for cabinetry.

Glass is often used for cabinet doors, providing a modern and elegant touch to cabinetry. It is available in a variety of styles and can be clear, frosted, or textured. Glass doors can also be combined with wood or metal frames for a more decorative look.

Metal is a popular choice for modern and industrial-style cabinetry. It is a strong and durable material that can be used for cabinet doors, drawers, and hardware. Stainless steel and aluminium are among the most popular types of metal used in cabinetry.

When choosing materials for your cabinetry project, it is important to consider your design style, budget, and the durability and maintenance requirements of each material.

Popular modern styles of cabinetry

There are several popular modern styles of cabinetry that are commonly used in contemporary interior design to suit a variety of tastes and preferences, from minimalist and functional to warm and cozy. Cabinetry styles can be influenced by country, culture, climate and demographic. Cabinet markers in Sydney eastern suburbs might even find client style choice different to Sydney north shore. Here are a few of the most popular styles:

Shaker Style:

The Shaker style of cabinetry is characterized by a minimalist design with clean lines, flat-panel doors, and simple hardware. This style is often used in modern kitchens and is known for its versatility and timeless appeal.

Transitional Style:

The transitional style combines elements of traditional and contemporary design. This style typically features clean lines, simple shapes, and neutral colours, while incorporating traditional elements such as raised panel doors and ornate hardware.

Rustic Style:

The rustic style of cabinetry is inspired by the natural beauty of wood and the outdoors. This style typically features rough-hewn wood, distressed finishes, and ornate hardware, creating a warm and cozy feel.

Contemporary Style:

The contemporary style of cabinetry is known for its sleek, minimalist design. This style often features flat-panel doors, simple hardware, and clean lines, with a focus on functionality and efficiency.

Industrial Style:

The industrial style of cabinetry is characterized by a raw and utilitarian design. This style often features metal or concrete elements, exposed hardware, and simple, functional designs.

High Gloss Style:

The high gloss style of cabinetry is a modern style that features glossy finishes on flat-panel doors. This style is often used in contemporary kitchens and is known for its clean and polished look.