Cabinet makers are often asked the question:

“What’s the best finish to use and why?” Let’s start by defining “What is a finish?” It’s not just a case of appearance but also about performance. A wood finish can do several things. It can enhance a surface, bringing out its natural beauty, showcasing the figure and wood grain and adding a depth to the quality of the appearance. The appropriate finish can protect from harmful ultra violet rays, water penetration, dirt marks, oxidisation and the effects of general wear and tear. They can colour a surface, hide imperfections and even change the look of the timber entirely.

Finishes usually consist of a resin suspended in a liquid (solvent), this allows it to flow onto the surface of the work, as it dries the solvent evaporates and the resin remains to form a hard layer, this is an evaporative finish. By contrast, a reactionary finish is one that undergoes a chemical change. A finish also preserves the timber it is applied to. So what finish do I use? In simple terms this is based on what type of cabinetry you will be covering, how you will be using it and where you will be using it. For instance, the surface of a cabinet exposed to sunlight breaks down, the skin of a cabinet is not unlike human skin and can be easily damaged if not protected. A finish can also be applied in a number of ways; it can be brushed, wiped-on or sprayed.

Brushable finishes

Shellac – a fast drying evaporative coating consisting of resin and alcohol, it is refined from the secretions of an insect which is native to South East Asia and is a very popular finish on period furniture. When brushed it can get quite thick which results in a rubbery surface.

Oil varnish – An attractive finish which tends to soak into the woods surface rather than sitting on top of it, this offers better adhesion and results in a more translucent appearance. It is a slow drying finish, yet durable, flexible and relatively resistant to solvents.

Polyurethane varnish – the addition of polyurethane to oil varnish, makes this a more durable product. It also has good scratch and heat resistant properties, but is harder to apply than oil varnish.

Spar varnish – A reactive finish used predominately outdoors. It is an extremely flexible and UV resistant. Tends to wear rather than peel or crack, can be applied to most surfaces as it has very good adhesive qualities.

Water- based varnish – UV stable, good stain resistance and fairly durable but don’t offer the richness of finish as do their oil counter-parts. They are however less susceptible to yellowing, unlike oils.

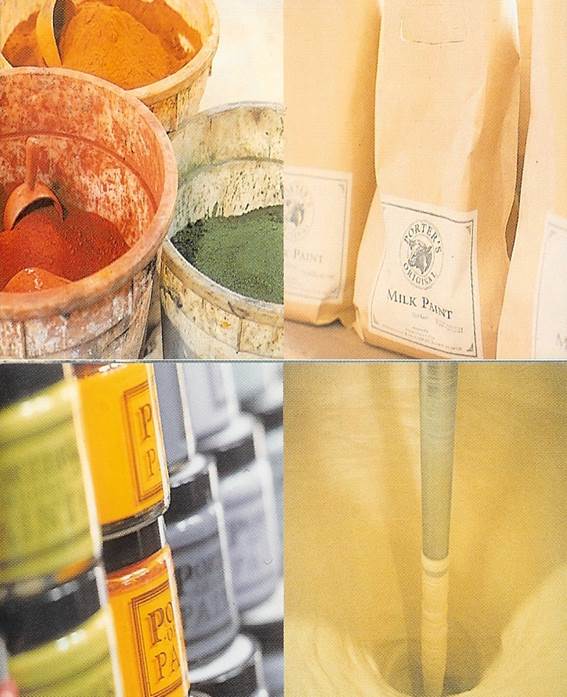

Milk paint – a traditional opaque finish, used for centuries by cabinet makers ,before the sale of commercially made paints first used in the 1900s on Shaker furniture. Used to preserve the timber, it has a rustic, chalky quality that softens and ages the appearance of furniture. It is made from milk by-products mixed with powdered oxide pigment to produce subtle, mellow colours. Usually coated in a wax finish to seal the surface and enhance the colour properties. It is made from elements that pre-date the use of petrochemicals and other toxic bases and solvents, it is biodegradable. The finished surface is durable and resists fading.

Acrylic resins – these water based coatings have a colourless clarity, easy to use and is resistant to yellowing which makes them useful over the top of white and light coloured paints. They are durable, have good UV stability, and decent stain resistance. Acrylic polyurethane – as with oil based varnishes, the addition of polyurethane to acrylic varnish, improves its scratch and heat resistance.

Wipe-on finishes

Shellac – makes a fantastic sealer coat for solid timber and can be finished with a wax coating. When applied in lots of very fine layers it results in French polishing, a strenuous process but a highly revered result.

Danish oil -a highly diluted reactive finish usually consisting of Linseed or tung oil. Because it is ultra- thin it loses a lot of its protective properties. It is very easy to use and gives that accustomed oil lustre.

Linseed oil –pressed from flax seeds this slow drying oil gives a very flexible film which is quite solvent resistant, often used to coat wooden spoons and salad bowls.( I used it a lot as a young chap to protect my cricket bats).

Tung oil – a natural reactive finish derived from tung nuts. Quicker drying than linseed oil and also more durable.

Wax – the simplest reactive finish, offers very little scratch, moisture or solvent protection and no heat protection, also the only finish you can use over the top of wax, is wax itself. It does however give a beautiful natural lustre and is very tactile. Carnauba wax is harder than bees wax and is extremely easy and satisfying to apply.

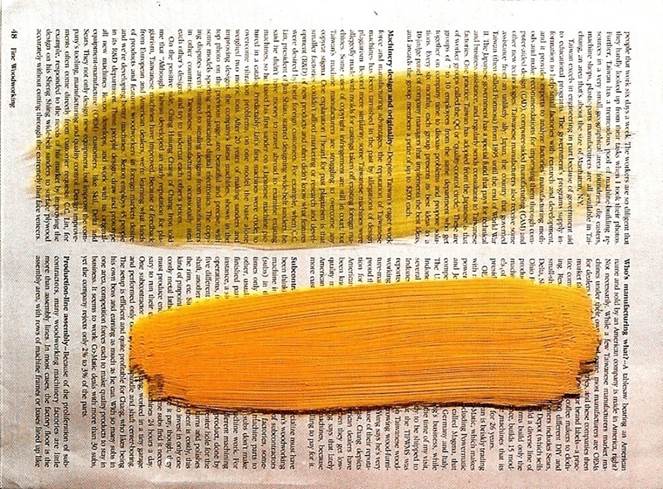

Pigmented and translucent stains

Stains – Wood stains consist of either, pigments, dyes or a combination of both. Pigmented stains are opaque and sit on top of the wood surface; dyes are translucent and penetrate the timber. It can be a very tricky procedure, colouring wood is an art and best undertaken by a professional.

Spray finishes

Shellac- yes it’s not a typo, shellac ticks all three boxes, although this is the least preferred method of application. Whether brushed, wiped – on or sprayed it offers the same film properties.

Lacquers – these are fast to apply and fast drying, they are perfect for spraying but high in volatile organic compounds (VOCs). Nitrocellulose is popular in wood working. A time- honoured finish but rather brittle. It offers good scratch and moisture resistance but poor heat and solvent protection. It has a propensity to chip and yellows with age but has great clarity and can be buffed to a high gloss finish.

Cellulose acetate butyrate (CAB) – It has very similar properties to nitrocellulose but not as brittle. Conversion lacquer– similar to catalysed lacquers in its properties but looks more like varnish.

Polyester – Seldom used as it is a very hazardous material and difficult to apply. It does however give a very fast build up due to a high solids content, this results in a very strong plastic coating that retains transparency.